Products Categories

Contact Info

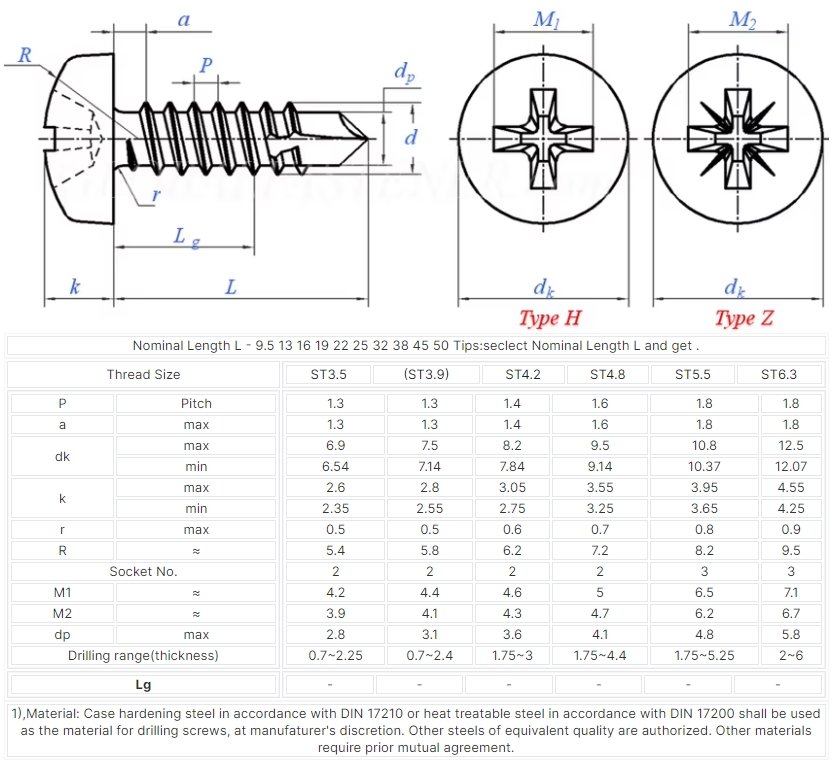

Pan Head Cross Recessed Sheet Metal Screws

● Product Type: Self Drilling Screws, Tek Screws, Sheet Metal Screws

● Product Name: Stainless Steel Pan Head Self Drilling Screws

● Head Type: Pan Head

● Groove Type: Phillips/Cross Recessed.

● Material: Stainless Steel 304 316

● Testing: Salt Spray Test

● Size: ST2.2-ST6.3

● Coating: Plain, Black Zinc, Black Oxide, etc

● Color: Silvery, Black etc.

PRODUCT DETAILS:

Building Roofing Tek Screws /Tornillos Pan Framing Head Self Drilling Screws

Pointed screws are the most common tapping screw. They have a pointed end to penetrate thin material such as sheet metal, and soft material such as wood and drywall. In thicker material, they generally need a starter hole.

Fastener product SS316 stainless steel DIN7504K hex flange head self drilling screw Cross Recessed Pan Head Drilling Screws.

Thread-forming and thread-cutting screws create reusable threads in metals and plastics. They require a drilled or punched hole to install. Thread-forming screws press threads into material for a tight, vibration resistant assembly, while thread-cutting screws require less driving torque and cause less stress on material than thread-forming screws.

Drilling screws save you time and effort by drilling their own holes, creating reusable threads, and fastening material in a single operation.

What material should I choose for my stainless steel self-drilling screws?

- 316 stainless steel — With high chromium (16%-18%) and nickel (10%-14%) contents, and 2%-3% molybdenum added. Our most corrosion-resistant stainless steel, with excellent resistance to chemicals and salt water, may be slightly magnetic.

- 18-8 stainless steel — Generally refers to stainless steel containing about 18% chromium and 8% nickel, similar to AISI 304. It is a general-purpose stainless steel with good corrosion resistance, especially in environments without chloride stress corrosion. 304 stainless steel has good processing performance and can be cold worked, but it does not have high hardness like 410.

- 410 stainless steel — With a high carbon content (0.15%) and a chromium content between 11.5% and 13.5%. Stronger and more wear-resistant than 316 and 18-8 stainless steel, with slight chemical resistance and magnetism. Not suitable for aluminum.

PRODUCTION PROCESS:

TESTING EQUIPMENTS: